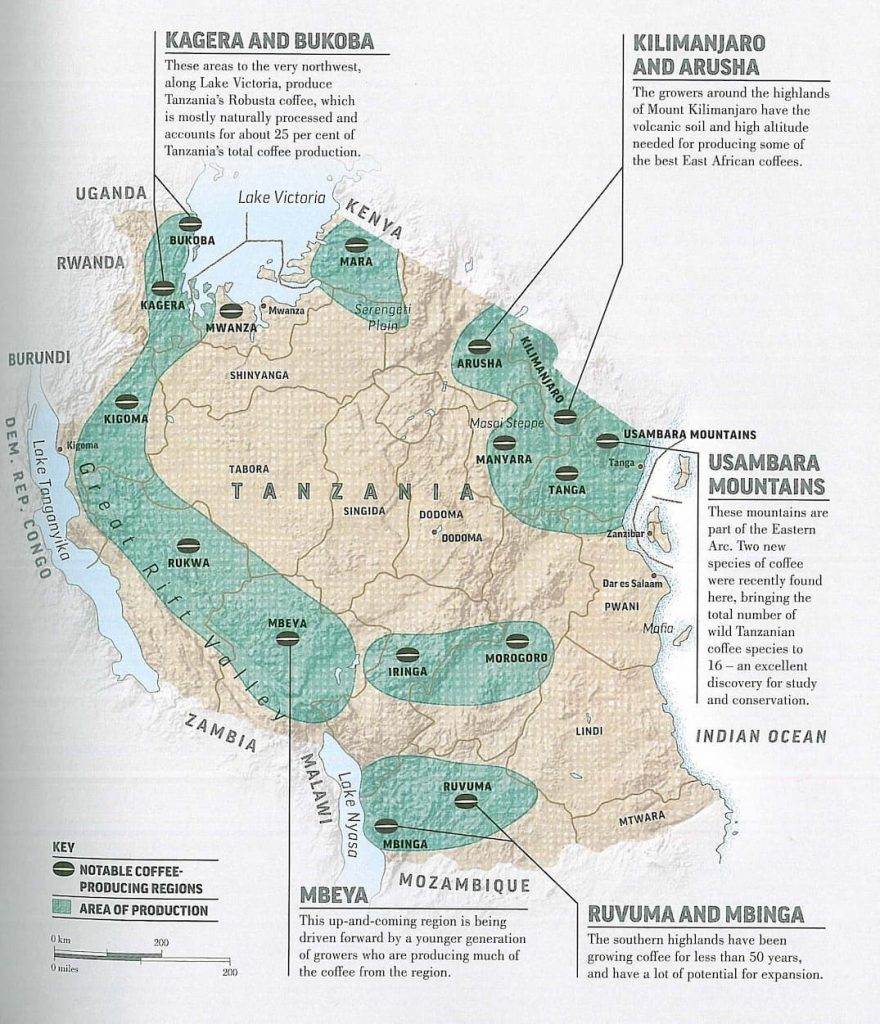

Tanzanian coffee flavors can be divided between Robusta and Arabica, full-bodied, sweet, naturally processed Robusta coffees near Lake Victoria, and washed, bright, citrus-flavored, berry-like Arabica from the rest of the country.

Coffee was introduced to Tanzania by Catholic missionaries in 1898. Today, a little Robusta grows in Tanzania, but most of the harvest is Arabica – Bourbon, Kent, Nyassa and the famous Blue Mountain. It is prone to major fluctuations in production, from 753,000 bags in 2014/2015 to 1,175,000 bags in 2018/2019. About 20% of Tanzania's export earnings come from coffee. The fruit yield per tree is low, adding to other growing challenges such as low prices and lack of preparation and equipment. Almost all coffee is grown by small landowners on family farms. About 450,000 families are involved in coffee cultivation, and the industry as a whole employs about 2.5 million people.

As in other African countries, coffee is sold at auction, but there is a "direct" window open for buyers who want to buy directly from exporters. This window allows you to, higher quality coffee to be rewarded with higher prices, creating a long-term sustainable production cycle.

TANZANIA KEY FACTS

PERCENTAGE OF THE WORLD MARKET 0,56%

HARVEST Arabica July-February; Robusta April-December

PROCESSES Washed Arabica, Natural Robusta

MAIN TYPES 70% Arabica Bourbon, Kent, Nyassa, Blue Mountain; 30% Robust

WORLD RANKING AS A MANUFACTURER on the 16th place

Tanzania Shimilangwada Coffee

Established in 1989, Shimilangwada is the second oldest farm in the Songwe region. Originally owned by a Swiss family who cultivated only 67 acres, the property was purchased in 2017 by Tanzanian entrepreneur, Mr. Nzunda, who bought the land in hopes of reviving the old trees. Since taking over the property, Mr. Nzunda has managed to double the area of productive coffee plantation and promote the quality of the products.

When it is harvest time, green coffee beans are manually selected and sorted into batches; separated from the area where they were harvested and the day they were picked and washed. The process begins by separating any under/overripe grains, along with any foreign matter, such as sticks or gravel. Next, the coffee is hulled using the farm's mechanical mill to remove the outer layer of fruit, later being sorted according to density. Usually, green beans are picked, sorted, and peeled all on the same day; with processing carried out in the evening.

Then, the coffee is put into fermentation tanks to remove the remaining mucilage. The beans stay here for between 24 and 72 hours and are checked every morning, depending on the atmospheric temperature. Once fermentation is complete, the beans are washed in cold clean water at the farm's washing station, before being transferred to hanging beds to dry naturally.

The coffee is spread on the hanging beds and turned regularly for even drying. For the first three days, the coffee layer is kept in the shade, away from direct sunlight. Subsequently, the coffee is then moved to beds under direct sunlight. The beds are covered in bright sun (at noon) so that the grains are not scorched, as well as when it rains to prevent rewetting. At night, the coffee is covered with polyethylene film to prevent dew buildup. The drying process will usually take between 10 and 11 days ; Load into bags only after the moisture content has reached 11.5% or lower.

Listen to the text of the article